FabLab at the SWC

Cutting-edge research and revolutionary breakthroughs demand fresh scientific approaches, intricately supported by specialised instrumentation for data acquisition and process control. The SWC FabLab is at the forefront, dedicated to catalysing and expediting innovative scientific research through the conceptualisation, development, and deployment of novel research instruments. Our FabLab team boasts multi-disciplinary expertise in engineering and electronics, empowering us to assess scientific and technical requirements, propose solutions, and engineer them into reality.

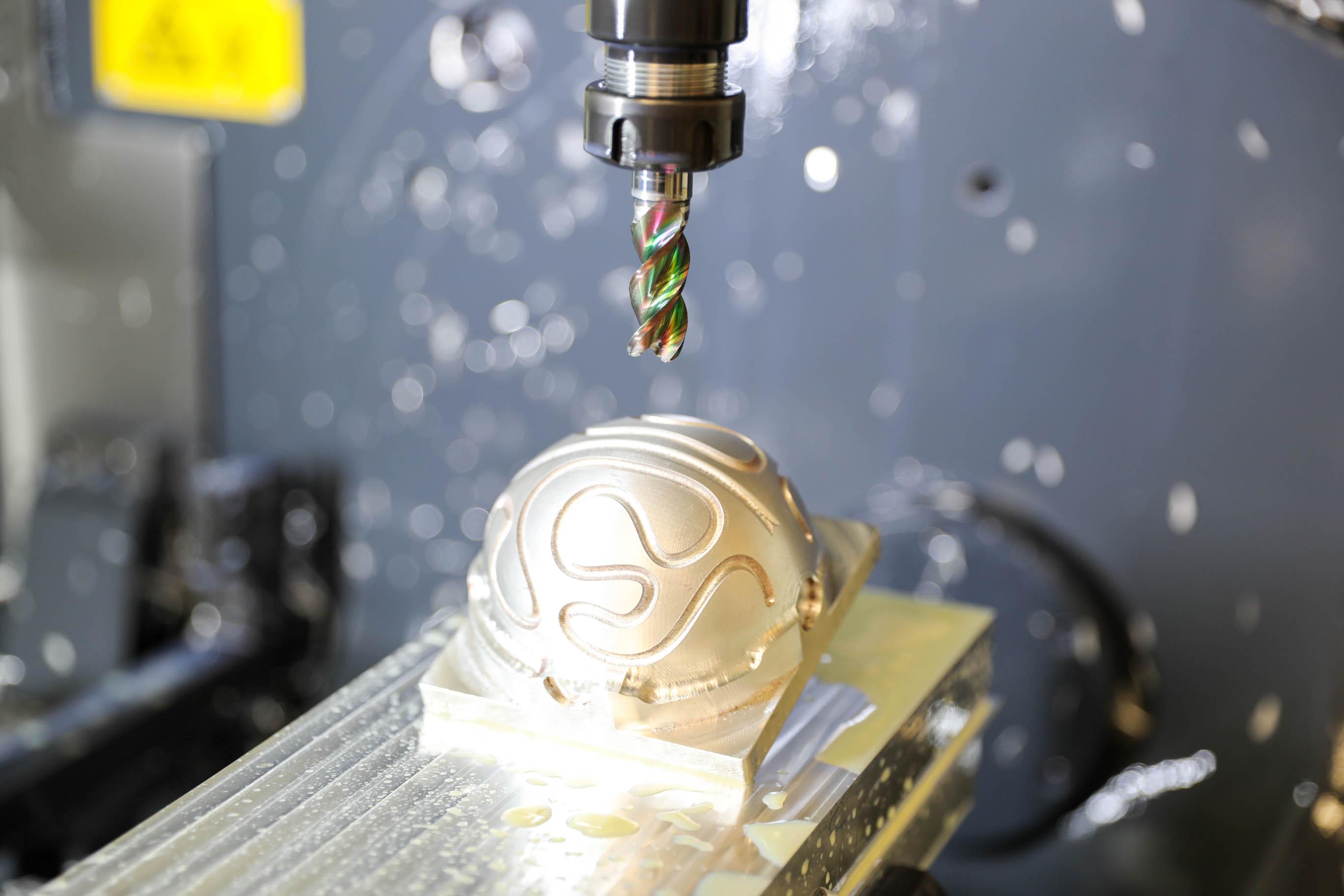

The dynamic landscape of scientific exploration necessitates the ability to swiftly design, construct, and refine solutions as research evolves. To facilitate this iterative development, our FabLab has made significant investments in state-of-the-art facilities equipped with cutting-edge design and manufacturing technologies. This includes rapid prototyping capabilities for electronic components, 3D printing, and precision machining, surpassing the limitations of commercially available solutions. Guided by highly skilled and experienced Mechanical and Electronics design and fabrication engineers, our FabLab team spearheads a dynamic MakerSpace. This multidisciplinary environment empowers scientists at all career levels to freely experiment and prototype ideas, leveraging mechanical fabrication equipment, laser cutters, and 3D printing machines.

In the pursuit of scientific discovery without constraints, the FabLab embraces continuous technological evolution. We foster this process through a harmonious blend of imaginative science and creative engineering, ensuring that boundaries are continually pushed, and new horizons are explored.

A connected team of mechanical design & electronics engineers

FabLabs are multiskilled specialists in design and manufacturing techniques for processes such as 3D printing, laser cutting and system integration. They are experienced in specialised disciplines such as electronics development and precision machining. FabLab utilise standardised digital manufacturing workflows from conceptualisation through to the final product. The standardised design software also enables scientists to participate and produce designs suitable for direct manufacture.

An innovative hub for connected mechanical design & electronics engineering expertise: At SWC FabLab, we pride ourselves on being a collaborative team of Mechanical Design and Electronics Engineers, working together seamlessly to bring innovative ideas to life.

Our FabLab members are not just skilled in one area; they are versatile specialists proficient in a range of design and manufacturing techniques. From the precision of 3D printing and laser cutting to the intricacies of electronics development and precision machining, we cover it all.

What sets us apart is our commitment to standardised digital manufacturing workflows. From the initial concept to the final product, our streamlined processes ensure efficiency and precision at every step. Our use of standardised design software not only facilitates seamless collaboration within our team, but also invites scientists to actively engage and contribute designs suitable for direct manufacturing.

At the FabLab, connectivity, innovation, and expertise converge to shape the future of mechanical design and electronics engineering at the Sainsbury Wellcome Centre.